Spiral wound

The most famous standards of the International Bureau of Weights and Measures (BIPM) in Sèvres, near Paris, are the meter and the kilogram. It's only a matter of time before the spiral-wound membrane is added to the list of standards, exemplifying something that simultaneously combines the best and worst features of membrane filters.

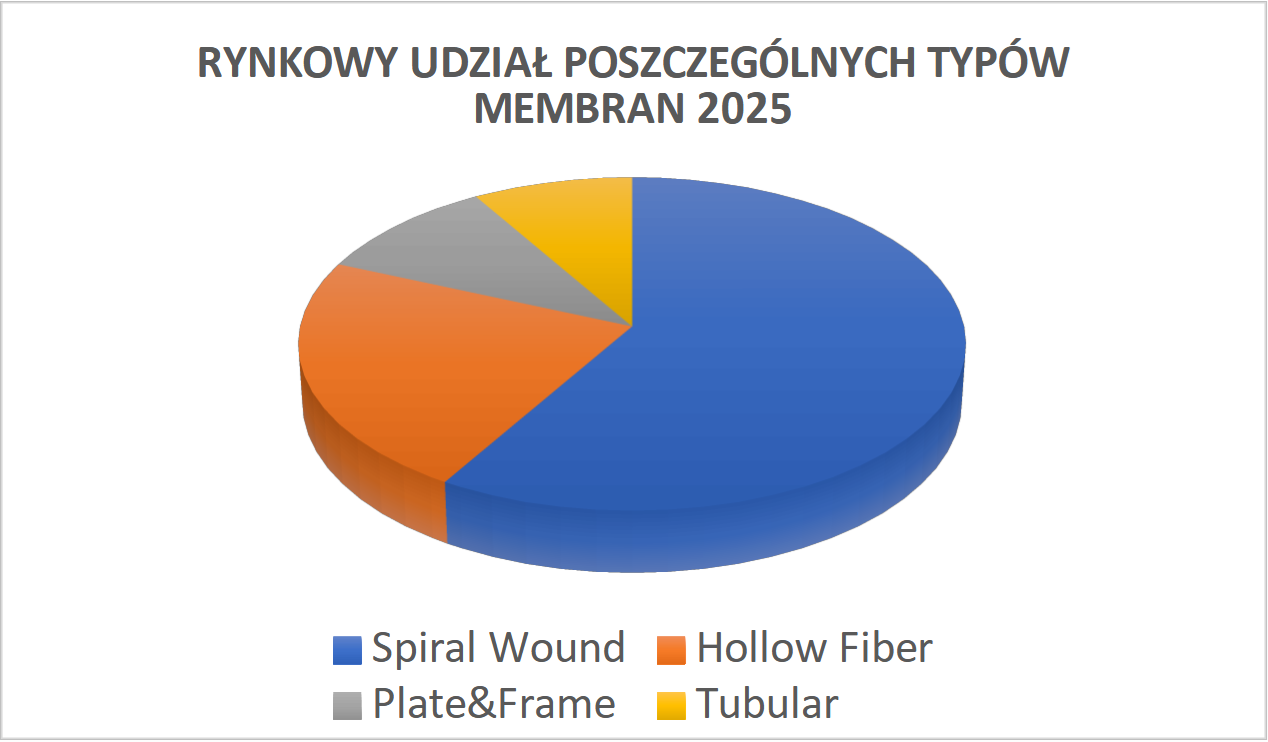

Spiral-wound membranes are the standard in water desalination and demineralization systems, accounting for more than half of the world's total membrane production [source: https://www.usdanalytics.com/industry-reports/membrane-filtration-modules-market]

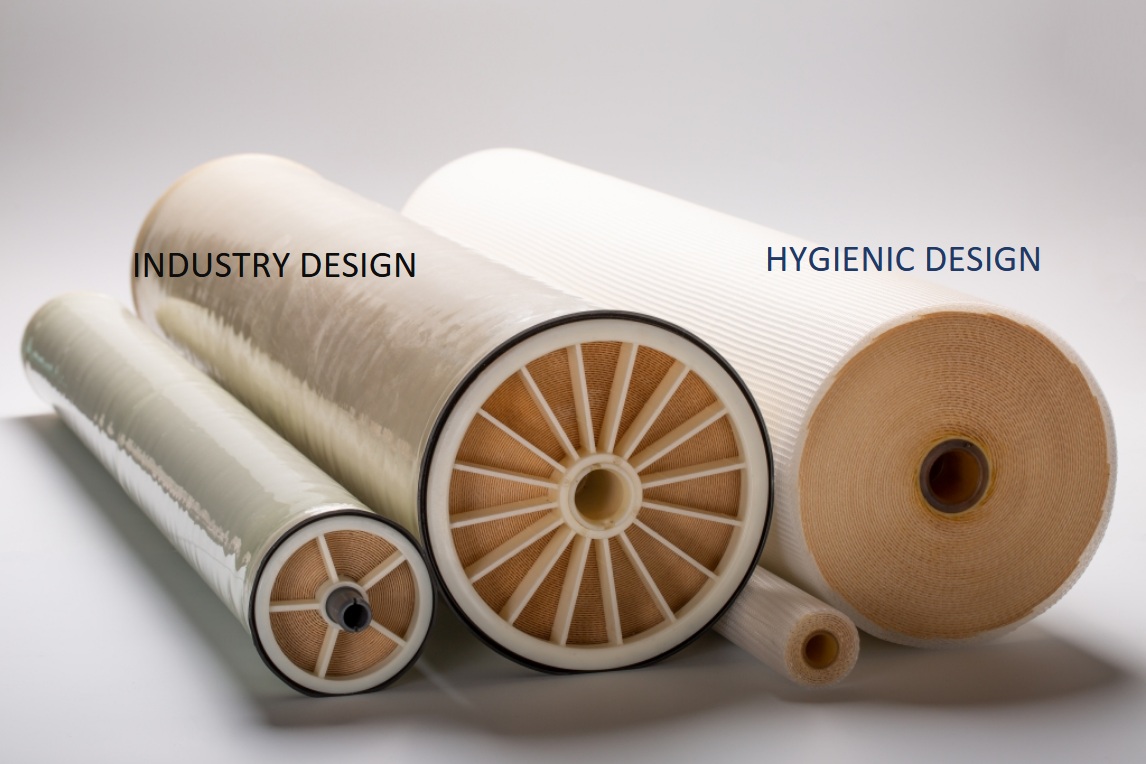

Spiral-wound membranes are simply flat membranes (exactly like plate membranes), but rolled multiple times into a roll, properly glued, and secured against unwinding. Depending on the roll securing method, the membranes are available in standard or hygienic versions. These are the exact same membranes, with the same parameters, but with a different external design.

The hygienic standard increases the likelihood of cleaning the spiral-wound membrane.

Hygienic standards increase the likelihood of cleaning a spiral-wound membrane, but do not guarantee it. Therefore, more and more spiral-wound membrane manufacturers are further modifying the outer coil design to increase this likelihood. The side photo below shows a TurboClean membrane from Mann Hummel.

Hygienic standards increase the likelihood of cleaning a spiral-wound membrane, but do not guarantee it. Therefore, more and more spiral-wound membrane manufacturers are further modifying the outer coil design to increase this likelihood. The side photo below shows a TurboClean membrane from Mann Hummel.

The spiral-wound membrane's main advantage lies in the membrane's packing density. Depending on the spacer used, the packing density of spiral membranes can exceed 1000 m²/m³, making them unrivaled in this respect, second only to capillary membranes.

Shear flow is the main cost driver for a working membrane. Spiral-wound membranes can be connected in series, allowing a single shear flow to operate up to five membranes simultaneously. The electrical energy consumption for shear flow management is the lowest of all membrane types, which is another undoubted advantage of spiral membranes.

This packing density, along with low electrical energy consumption, explains the largest market share of spiral membranes.

However, the spiral wound membrane also poses problems.

Spiral-wound membranes can only operate with feedstock with a low silt density index, also known as the membrane clogging index (Silt Density Index). Other definitions of this index, such as the Fouling Index (FI) or the Colloid Index (KI), can also be found in the literature, but they directly or indirectly refer to the same measured value. What does this mean in practice?

The feedstock fed to spiral-wound membranes must be dedusted. Feeding the feedstock with slurry causes physical blockage of the membrane feed channels.

Spiral-wound membranes also do not accept fat fractions or accept them only conditionally. Therefore, it is recommended to treat these fractions as slurry during feedstock preparation.

Furthermore, the design of the spiral-wound membrane does not accept feedstock with high viscosities. Even with an 80-mils spacer, flow blockage on the concentrate side can occur, leading to irreversible membrane damage. Therefore, it is crucial to control the increase in dynamic viscosity as the filtration process progresses.