Membranes

Installation of specific membranes type should be preceded by an appropriate analysis. The type of used membrane determines the construction of the entire installation. Once one type of membrane construction is installed, it is very difficult to change to another type as well as the cost-effectiveness of such a modification is questionable. The following table may be helpful in choosing a membrane. We reserve that the data presented is intended to help in general understanding of the problem.

|

TYPE OF MEMBRANE |

inorganic |

ORGANIC / POLYMER |

|||

|

Ceramic |

Flat |

Tubular |

Spiral |

Spiral HpHt |

|

|

Cut-off available |

MF, UF, NF |

MF, UF, NF |

UF, RO |

NF, RO |

MF, UF |

|

Material |

Inorganic oxides TiO2, ZrO2, AlO3 |

Polymer, mostly PES |

Polymer, mostly PVDF, but also PS, PES |

Polymer PA as well as PES |

Polymer PES |

|

Process mex temperature |

<250°C |

<75°C |

<65°C |

<50°C |

<60°C |

|

pH of process |

0,0÷14,0 |

1,0÷13,0 |

1,5÷10,5 |

4,0÷10,0 |

2,0÷10,0 |

|

Solvent resistance |

GREAT |

WEAK |

LIMITED |

WEAK |

|

|

REGENERATION / CLEANING |

|||||

|

Steam sterilisation |

121°C x 30min |

NO |

|||

|

Chlorination |

<300ppm |

<200ppm |

<0,1ppm |

<200ppm |

|

|

Peracids disinfection |

NO LIMITS |

Not allowed |

<150ppm x 15min |

||

|

Cleaning max temperature |

<95°C |

<75°C |

<65°C |

<60°C |

<85°C |

|

pH during cleaning |

0,0÷14,0 (2,0÷14,0 FineUF) |

1,0÷13,0 |

1,5÷10,5 |

1,0÷12,0 |

1,8÷12,5 |

|

HANDLING / SERVICE |

|||||

|

Backwash |

YES |

NO |

|||

|

Backflush |

YES |

STRICTLY LIMITED |

|||

|

Chemicals allowed |

Except HF Except HNO3 - FineUF |

Dedicated cleaning agents |

NaOH, HNO3, NaOCl, H2O2 |

Dedicated cleaning agents |

|

|

Mechanical shock resistance |

VERY LOW |

MEDIUM |

GREAT |

||

|

Thermal shock resistance ΔT |

VERY LOW |

GREAT |

|||

|

Energetic efficiency |

F |

D |

C |

B |

|

|

Water consumption during cleaning |

|

|

|

|

|

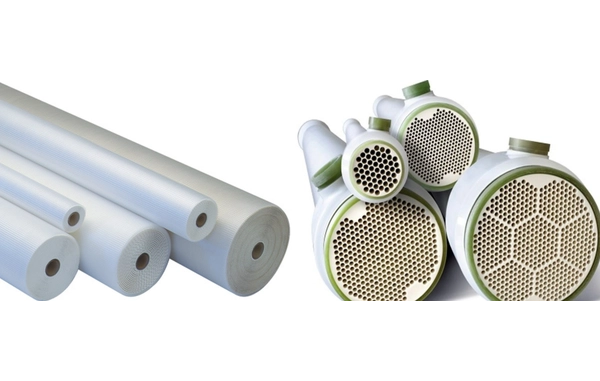

As can be seen, the functional characteristics of ceramic membranes still set the direction of development for polymer membranes. Nevertheless, it should be noted that the energy efficiency of installations based on ceramic membranes is the lowest.

So when should ceramic membranes be used in the installation? When the characteristics of the processed material make it impossible to use polymer membranes or when saving water is critical case.

All types of membrane except flat organic Intermasz can supply you.

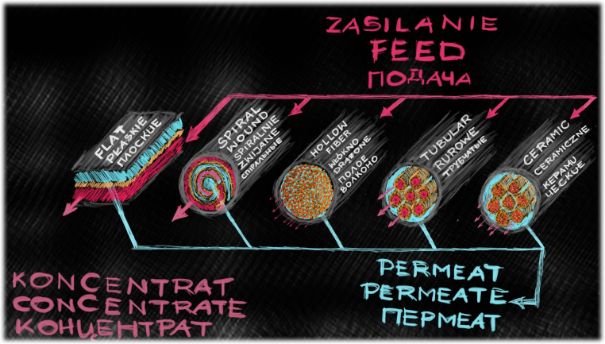

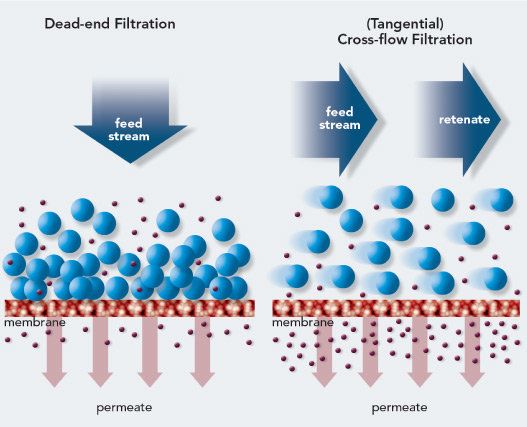

From the point of view of raw material feeding, membranes can be divided into two groups: dead-end and cross-flow. Please see the figure below.

Most of the costs associated with the separation process on the membrane in the cross-flow system are related to maintaining the appropriate value of shear flow which removing membrane fouling. In the case of dead-end solutions, there is no need to induce flow parallel to the membrane. Therefore, from the point of view of the economics of the process, dead-end solutions could be considered simply cheaper... yes could be.

As can be deduced from the graphic above, the potential to create fouling on the membrane as well as to change the characteristics of the permeate during the process is greatest for dead-end solutions. Therefore, at Intermasz, we believe that dead-end structures are not the best available technique (BAT) and we do not develop solutions of this type..